Michael Smith of Algae Aqua-Culture Technology’s Green Power House™ is an Algae Biofuel Case Study and environmental innovator of micro algae grow and micro-farming. His love for Montana’s natural surroundings combined with his software and engineering skills manifested a green bio refinery into a reality. The first of its kind 5,000 square-foot, eight-sided, three-story dome structure is located at F.H. Stoltz Land and Lumber in Columbia Falls, Montana. The concept behind the GPH™ is to generate power, but also to regenerate natural resources using carbon-negative technology.

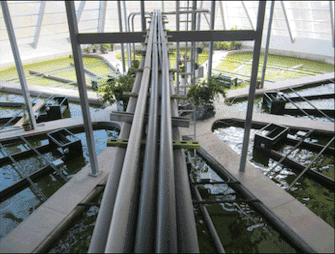

“Imagine walking into a space filled with hanging gardens and diffused with dappled light, Eight shallow, wedge-shaped vats of algae comprise most of

the floor space in the main part of the building. “These algal raceway ponds are the photobioreactor,” explained Smith, “the first of the three components of the Green Power House that serves essentially as a biological solar cell."

“It’s a closed-loop biorefinery,” he said, “that is based on simple, longstanding, biological principals. It uses local algae, waste heat and wood waste to produce a unique and highly effective fertilizer that rejuvenates depleted soil.”

A component of the “closed-loop” green network is eight algae raceway ponds that hold about 1500 gallons is what creates this algae microfarm. The algal channels produce energy-rich algae fueled by woody biomass – including wood waste from the mill, and also water, sunlight and carbon dioxide. Micro algae grow extremely fast and a pound of fresh algae can generate a 1,000 more btu’s than a pound of coal.

The harvested algae get pumped into photobioreactor tanks where it absorbs carbon dioxide and nitrous oxide generated from the Organic Carbon Engine™ (OCE).

The OCE also performs other functions. It gasifies wood chips and other wood waste using high heat to partially run the system, and then channels left-over energy to heat exchangers to regulate the photobioreactors and anaerobic bioreactor.

The micro algae grow then enters the second component, the anaerobic bioreactor which converts the algal biomass to methane and hydrogen gases, and algae ‘manure’ – a nutrient-rich concentrated substance. The gases produced can be converted into electricity and other forms of energy to power the mill.

The operation also generates a mix of biochar, the organic carbon created from pyrolysis of waste biomass and algae digestate which creates high-grade organic fertilizer and soil amendments.

Each AACT component utilizes a proprietary artificial intelligence system – Autonomic Networked Technology (ANT), and each integral part can work independently or together. These bioprocessors allow each component to adjust its performance imitating the workings of nature.

A half-acre of vertical micro algae grow microfarming to grow organic food could also be sustained in the atrium space of the greenhouse.

His Algae Biofuel Case Study Algae Grow Products Are:

- Organic Soil Fertility Conditioners/

- Soil Regenerating Products

Secondary Products Include:

- Methane/Syngas

- Greenhouse space for crops

- Electricity-‐250kWh of power can be produced continuously through the biorefinery.

- Bio-‐oils

- Heat for industrial applications, such as drying kilns

The greenhouse also generates methane, bio-oils, syngas and thermal energy that can be utilized to run the greenhouse and power electricity.

Water is also recaptured through pyrolysis and utilized on site.

Here are some interesting facts relating to Green Power House™ facilities:

- One GPH™ and one OCE together can produce 1250kW of energy continuously, or 6 MWh/day. This works out to $264,000 annual savings, based on a national average power rate of $0.12/kWHr.

- Each GPH™ only uses 5kW per day to run, in comparison, the average American home consumes about 100 kW per day.

- Conservatively one GPH™ can power 100 homes with electricity.

Here are several species of algae worth considering for small scale production:

- Spirulina has been the most extensively harvested algae since the 1970s. For over 40 years, thousands of tons of Spirulina have been marketed as dietary and nutritional supplements and feed supplements in aquaculture and poultry industries. Big commercial producers cultivate it in the USA, Mexico, China, Thailand, India and other countries, and there are numerous microfarms and algaepreneurs in Europe, Africa and Asia.

- Chlorella is a single-cell, water-grown microalgae, and the first to be commercially harvested starting in the 1970s and sold as a food supplement. It is mainly cultivated outside in mineral-rich freshwater ponds under direct sunlight in Japan, China and Taiwan for global consumption. Chlorella is also commercially produced in closed pure tank culture systems using a fermentation process in Korea.

- Dunaliella is a type of green micro-algae found in highly concentrated sea salt fields in places like Australia and Israel. It is commercially cultivated and sold as a food supplement for its beta carotene and anti-oxidant benefits. Dunaliella is produced different ways – from comprehensive low-technology in lagoons to high cell density industrial systems.

- Haematococcus is raised in both open-air ponds and closed systems as the main source for Astaxanthin, a carotenoid pigment. Humans mainly consume it as an anti-oxidant food supplement. It is also used as a feed supplement for animal and aquaculture consumption like salmon, crabs, shrimp, chickens and egg production.

- Schizochytrium are marine microalgae that produce rich nutrients and developed as a source of docosahexaenoic acid (DHA) – vegetable-like oil that contains an essential polyunsaturated fatty acid. DHA is also commercially grown from microalgae by fermentation in vats, and widely used as a food supplement in infant formulas, food, beverage and animal feed products.

- Aphanizomenon flos-aquae are blue-green algae that use the available nitrogen during harvest season from Klamath Lake in Oregon, creating massive bloom of nutrient solution. Condensed tablets of powdered A. flos-aquae are sold as a dietary food supplement.

- Botryococcus braunii is cultivated for the hydrocarbons it produces for conversion into algae biofuel.

- Nannochloropsis is being developed for alga biofuel and the energy-rich nutritional food source omega-3 oil.

What Algae Aqua-Culture Technology and the GPH™ as an Algae Biofuel Case Study system has proven that micro algae grow and microfarming can function in all climates, create jobs, produce fuel, grow healthy soil and food for communities all over the world.

You also be interested in...

The Algae Biodiesel Process

The algae biodiesel process is fairly straight-forward, however the devil is in the details. Read More

The Two Biggest Mistakes in Algae Biofuels

Without a doubt, The Two Biggest Mistakes I saw as a biofuel consultant in advanced biofuels were...Read More

Algae Biofuels: Separating Myth From Fact

Lot so wild stories and wild claims being made in the algae biofuels space. Sifting through the flotsam of cyberspace isn't easy... Read More

The Algae Revolution Has Begun

I learned more from your eBook than spending $6,000...

Dear David,

I have learned more from your e-book than spending $6,000 going to the Algae World 2009 Conference in Rotterdam. Do you have the same manual for Jatropha? Many thanks,

Thanks in advance

Perpetual Prosperty Pumps, Africa