Why Algae To Biofuel? Here are just a few reasons:

- Much greater productivity than their terrestrial cousins

- Non-food resource

- Use otherwise non-productive land

- Algae can utilize saline (Salt) water

- Can utilize waste CO2streams

- Algae can be used in conjunction with waste water treatment

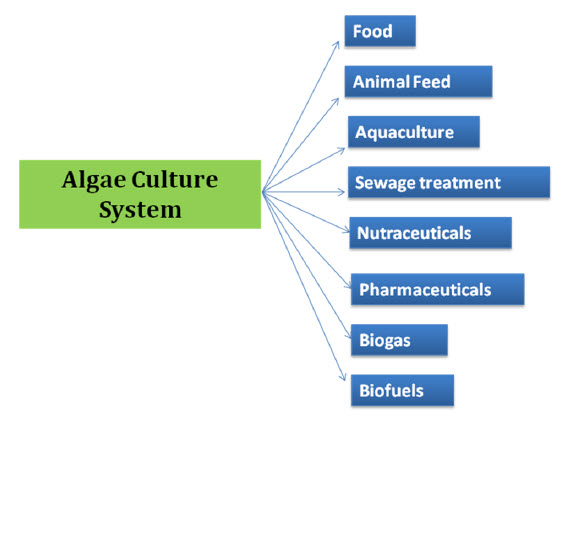

- An algal biorefinery could produce oils, protein, and carbohydrates

- Algal cultivation can be 50x more productive than traditional crops

- Potential for culture in areas not used for crop production

- Desert land

- Ocean

Co-products and By-Products Are Equally Valuable Commodities

- Co-products from the algae, (omega-3 oils) depending on strain, can bring as much as $3,000/ton USD

- Animal and Fish Feeds are currently selling for $2000/ton USD

Cost Considerations

- Can use wild algae for ethanol production = free algae inputs

- Raceway ponds are economical to build.

- Supporting mechanical infrastructure costs can be offset with solar energy inputs.

Wild algae

- Have to be fast growers to survive in nature

- Algae generally contain <10% oil (lipid)

- Generally contain high carbohydrate >50%

- Can be grown in open raceways without fear of contamination

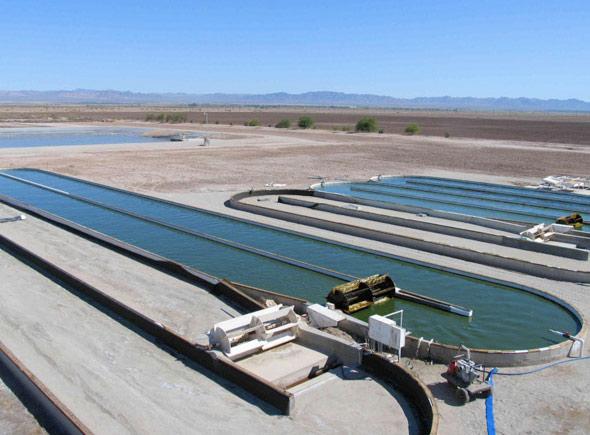

Using Raceway Ponds

- Raceway ponds are low cost installations ($75 000/ha)

- Ponds consume very little power (10 kW/ha)

- Starch to ethanol conversion plant is relatively expensive and energy intensive (distillation)

High oil producing algae

- Are slower growers than wild algae – double every 2-3 days

- Can be selected for maximum oil content – 50% not unusual

- Need to be grown in protected environment – typically PBR’s

- Most algae oil can be used for biodiesel production

Algae To Biofuel With Photo bioreactors (PBR’s)

- Allow tight control of growing environment

- Optimize light usage

- Are capital intensive

- Are generally power intensive (300 kW/ha?)

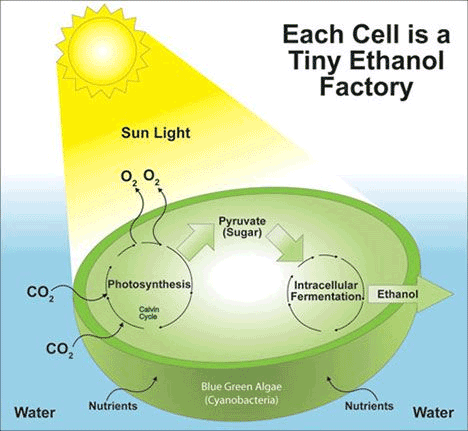

Why algae to biofuel? Put simply, lipids in algae oil can be made into biodiesel, while the carbohydrates can be converted to ethanol. Algae are the optimal source for second generation bioethanol due to the fact that they are high in carbohydrates/polysaccharides and thin cellulose walls.

Currently bioethanol is produced by fermenting sugars, which in the case of corn are derived from hydrolyzing starch. Algae species starch contents over 50 percent have been reported. With new technologies, cellulose and hemicellulose can be hydrolyzed to sugars , creating the possibility of converting an even larger part of algal dry matter to ethanol.

You might also be interested in...

The Algae Biodiesel Process

The algae biodiesel process is fairly straight-forward, however the devil is in the details. Read More

The Two Biggest Mistakes in Algae Biofuels

Without a doubt, The Two Biggest Mistakes I saw as a biofuel consultant in advanced biofuels were...Read More

Algae Biofuels: Separating Myth From Fact

Lot so wild stories and wild claims being made in the algae biofuels space. Sifting through the flotsam of cyberspace isn't easy... Read More

The Algae Revolution Has Begun

David, just read through your book on algal biodiesel. Nice layout, easy to read with emphasis on building from local materials and good optimism. We may use some of these ideas for our engineering senior design course this year on biofuels production. Thanks..

Professor of Biosystems Engineering